Skip to content

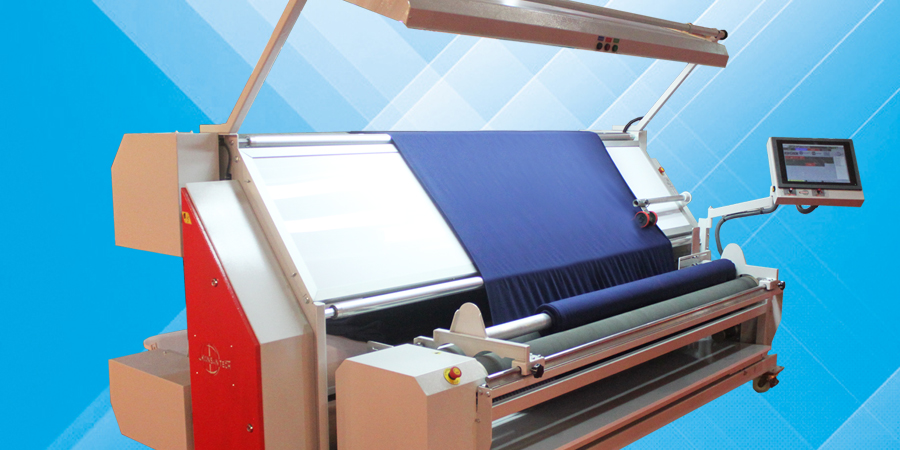

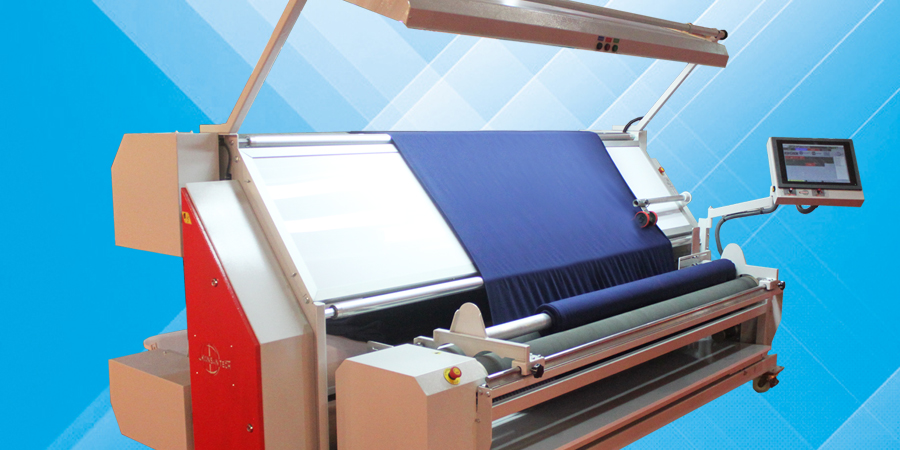

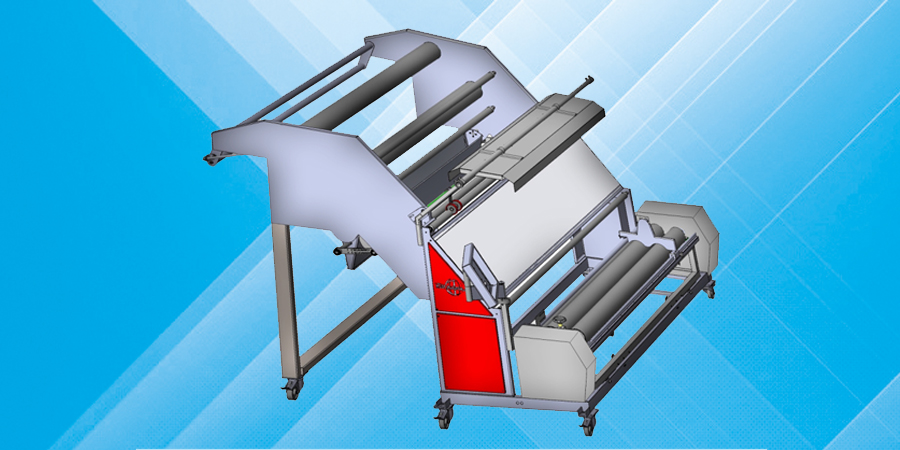

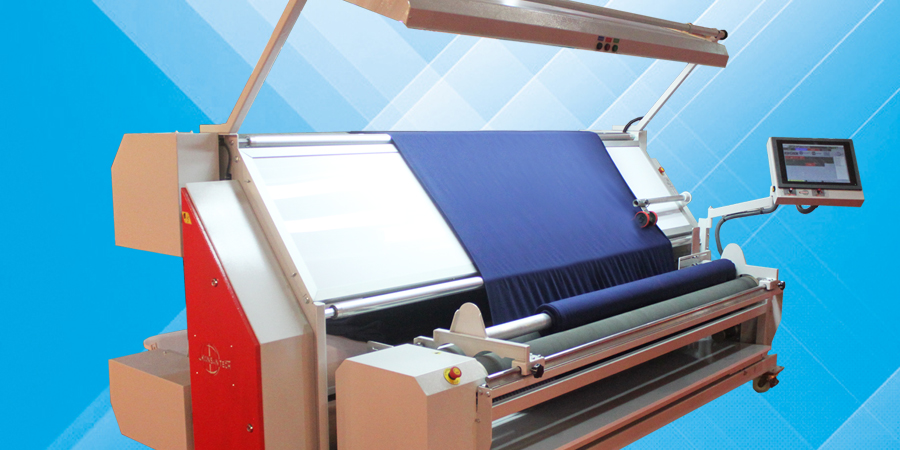

Roll to roll

Fold & Roll

Heavy-Duty Roll

Custom Design

SPECIFICATIONS

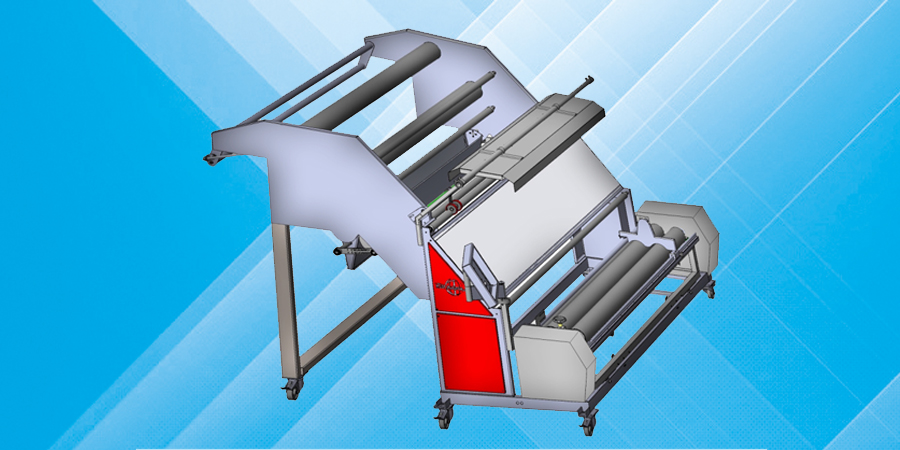

Motorised fabric plaiting(flat folding) system that enables operation from roll to plaiting, plaiting to roll and plaiting to plaiting.

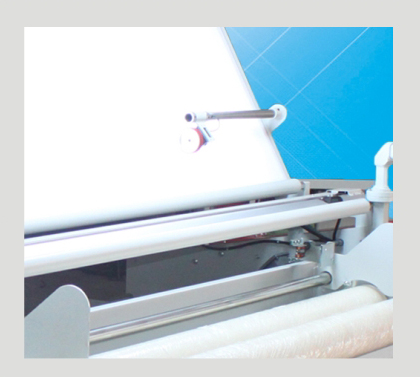

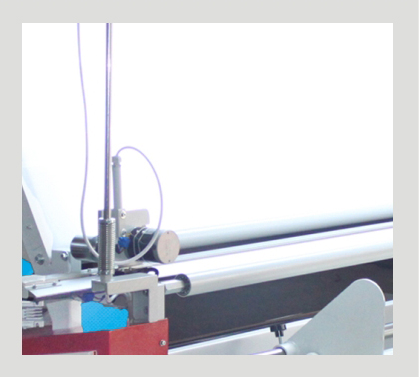

Surface Drive System (SDS) that prevents the stretch due to roll diameter changes during rewinding and unwinding

True Tension Control (TTC) is possible through speed difference adjustment between the unwind and the rewind units with individual motors

Operator Tension Adjustment (OTA) feature allows the relaxed rewinding of high stretch Lyrca fabrics

Long-life rubber coating on unwind and rewind rollers

Top and bottom light boxes with two level settings

Strong frame construction for long life and vibration-free operation

Length programmable

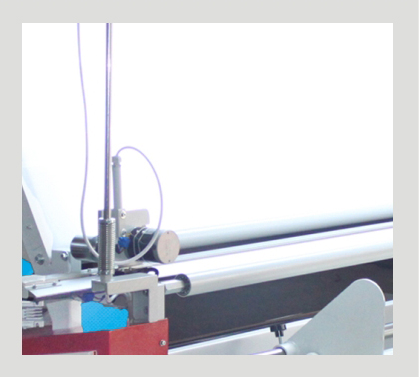

Roll-end optical sensor

Motorised Cross-Cutting device to produce rolls at pre-programmed lengths (Optional)

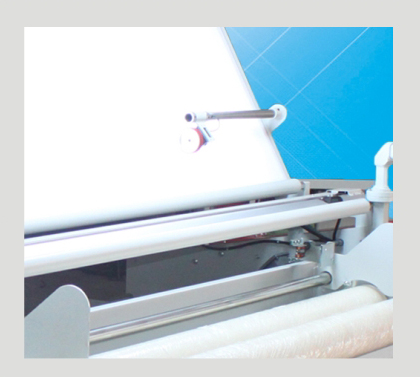

Optical edge alignment to produce rolls with straight edges (Optional)(KKONDEF)

Electronic Data Integration System (EDIS)(Optional)

15.6″ Industrial Touch-Screen PC (Windows™). Suitable for gloves

Defect Registry System:

- Up-to 40 defect buttons can be defined

- Unlimited Defect registry for each roll

- .CSV file output

Wi-Fi or Ethernet network connectivity. Web-based application for viewing Advanced Defect Reports across the company PCs and mobile devices

Updates and Support through remote connection.

Technical Specifications – KKONDE

| Maximum Fabric Width |

Maximum Fabric Roll Diameter |

Maximum Fabric Weight |

160cm

…

350 cm |

Max. 50cm

Min. 10cm |

150 kg |

| Maximum Speed |

Machine Width |

Machine Length |

30 m/min |

175 cm |

Fabric width

+65 cm |

| Machine Height |

Machine Weight |

Electricity |

193 cm |

610 kg

…

750 kg |

220 VAC

50 Hz |

OPTIONS

OPTICAL EDGE ALIGNMENT

MOTORISED CROSS-CUTTING DEVICE

15.6″ INDUSTRIAL PC WITH

TOUCH SCREEN (Windows™)

Ethernet connection to company network (Options)

Pc report viewing application (Excel Format)

Weight scale

Barkod reader

Detailed Information Form

error: Content is protected !!